Hammer paint is composed of a powder, pigments, additives, solvents composed of decorative products.

Form

The hammer paint by isocyanate component, acrylic resin containing hydroxyl group and aluminum powder, pigments, additives, solvents composition.

Characteristic

A clear pattern, bright color, convenient construction.

Advantage

1, film smooth, hard, beautiful decoration.

2, strong adhesion, flexibility, abrasion resistance, scratch resistance, resistance to impact.

3, good water resistance, oil resistance, chemical corrosion resistance.

Use

The hammer paint used for coating a household electrical appliance, motor, water pump, a speed reducer, instrumentation, instrumentation and other metal decorative paint protection.

Corrosion of hammer paint

Definition

Hammer paint damage cause film under corrosion

The causes of

1 sand erosion damaged film metal layer, then tend to appear in the film under corrosion, cause blistering or off.

The corrosion of the metal layer 2 hammer oil machinery paint cover under not completely clear, leading to corrosion deterioration and rapidly destroyed.

3 paint covering metal layer without gloves people touch, or aggregation encountered metal pretreatment chemicals, grinding paint remover water, pollution of metal contact.

Prevention

1 may be subjected to mechanical damage paint part, in the production or repair, must be sprayed paint protection can resist the erosion of sand

The 2 metal layer exposed must be thoroughly to remove surface grinding, and pit so rust trace

3 exposed metal must pass through the metal pretreatment agent and rust agent processing

4 do not hand contact has good coating the metal pretreatment of the metal part, however, must be primer process in 30 minutes, to avoid corrosion re formed remedial

Prolapse of paint, metal outside until now, re spraying machinery paint.

Technical indicators

Color and appearance: colored light

Dry film thickness: 40 m

The wet film thickness: 32 m

Dosage: 107g/m2 theory

Fire protection standard: grade 0, no burning

Flash point: 24 degrees

Construction of reference

1 adopting a spraying method construction.

2 can a spray of flowers or multiple spraying flowering, construction interval between the bottom paint is more than 24H, finish between 15-30 minutes.

3 with the paint before B mix, according to a: B =1:4 proportion mixing paint stirring, placed the construction after 10-15 minutes. Paint a two-component mixed after use for a period of 8 hours.

4 hammer paint the best construction conditions for 25 + 5 degrees C, relative humidity is less than or equal to 75%, may be appropriate to increase the amount of component a rainy season in the humidity big.

With 5 construction tools, must be timely and thinner clean.

Storage and transportation

1 of the hammer paint should be sealed and stored in a cool and dry place, is strictly prohibited in the sun, rain, storage temperature at 0-30 degrees C.

2 of the hammer paint product storage period since the date of production respectively: group A of not less than 6 months, the second component is not less than 12 months, more than the storage period, after inspection, performance did not change, still can continue to use.

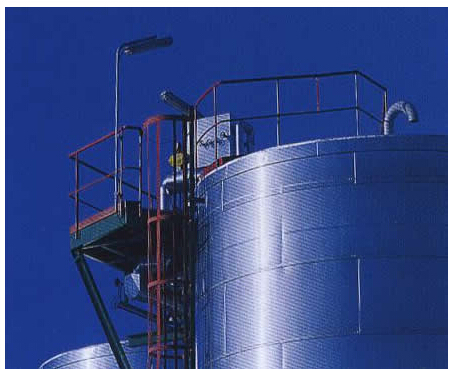

Hammer application effect of hammer paint map